Mobile marine service business support a critical segment of the maritime industry by providing on-demand repairs, inspections, and technical upgrades directly at marinas, docks, or private locations. Many business owners want to optimize their marine service business

As vessel systems continue to grow in complexity—particularly with the integration of advanced electronics and propulsion technologies—the demand for fast, localized service has increased.

To remain competitive, operators must refine their processes, reduce administrative friction, and deliver consistent results. Streamlining workflows, improving field-to-office communication, and adopting integrated platforms are now central to maintaining operational control and meeting customer expectations.

What Are Mobile Marine Service Operations?

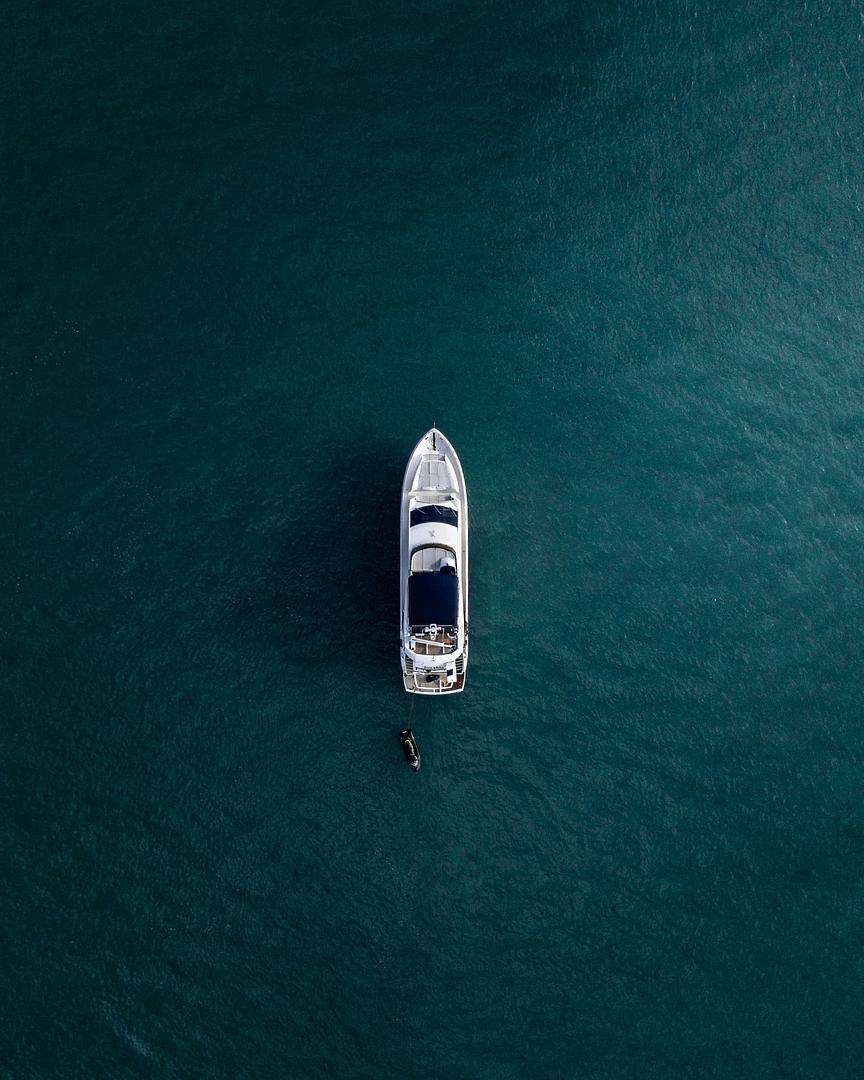

Mobile marine service business refer to field-based technical services that address maintenance, repair, or upgrades on vessels without requiring relocation to a central service yard. These business involve skilled technicians who travel to the customer’s location, equipped with the necessary tools, diagnostics systems, and replacement parts to complete work on-site. The approach supports a broad range of vessels—from trailerable boats stored offsite to large yachts moored in private slips—providing a flexible alternative to shore-based repair shops.

Why Is Efficiency Important?

Efficiency in mobile marine service businesses directly influences job profitability and technician utilization. Optimized routing tools and digital job queues allow technicians to complete more appointments per shift without compromising precision or safety standards. Client-facing performance metrics such as arrival accuracy, service duration, and issue resolution speed now serve as key differentiators in the marine service market.

Common Types of Mobile Marine Services

Mobile marine technicians address service demands that vary widely by vessel type, operating region, and seasonal usage. These professionals must execute repairs and preventive tasks in non-controlled environments—often in tight quarters, under time pressure, and without access to full shore-side infrastructure. The range and complexity of service offerings reflect this field-based adaptability.

Engine Systems and Propulsion

Engine performance directly affects vessel safety and owner satisfaction, making propulsion systems one of the most service-dependent areas in mobile marine business. Field technicians carry tools and diagnostics equipment to perform cylinder compression tests, sensor recalibrations, and throttle control inspections. For diesel systems, injector cleaning and aftercooler servicing are routine requests, particularly on commercial or high-hour vessels.

Electrical, Navigation, and Control Systems

With the proliferation of digital switching and vessel automation, electrical diagnostics now require both circuit-level and software-level expertise. Mobile technicians are expected to service voltage regulators, smart alternators, and lithium battery bank systems, often integrating new components into existing 12V/24V hybrid power architectures. Inverter-charger systems and shore power transfer switches are also routinely assessed for load balancing and fault isolation.

Navigation system installations increasingly involve configuring multi-function displays (MFDs), integrating proprietary software suites, and updating firmware for radar and sonar modules. Field professionals also calibrate heading sensors and fine-tune waypoint settings to match route profiles. This work supports vessel operators who depend on accurate overlays and autopilot behavior, especially in low-visibility or offshore conditions.

Exterior and Interior Preservation

Vessel owners continue to prioritize cosmetic and structural upkeep as part of long-term asset protection. Mobile detailing services include UV polymer coatings, stainless steel restoration, and non-skid deck treatments. In freshwater regions, acid-based hull washes are often replaced with biodegradable, lake-safe alternatives that comply with local environmental regulations.

Within the cabin, services now extend beyond visual cleaning. Technicians perform HVAC duct sanitization, odor neutralization using ozone generators, and dehumidifier setup to prevent mold recurrence in high-humidity areas. These offerings are particularly relevant in areas with limited storage ventilation or where vessels remain sealed for extended periods.

Where Do These Services Typically Operate?

Mobile marine service businesses are structured around accessibility and responsiveness. Their delivery model enables service teams to bypass traditional yard logistics and instead reach vessels where they’re moored, stored, or staged—drastically reducing service lead times and increasing client satisfaction.

Marinas, Slips, and Docking Facilities

Marinas remain the most frequent service point, especially for seasonal maintenance and electronics integration. Vessels docked here range from compact cruisers to large yachts, often positioned in close quarters with limited maneuvering space. Many marinas operate under strict safety and insurance protocols, requiring pre-approval for contractors and specific documentation for vendor access.

Private Residences, Yacht Clubs, and Gated Facilities

Servicing vessels at private docks or club slips involves a different service cadence—one that prioritizes discretion, tailored communication, and often, premium service expectations. These locations may lack auxiliary infrastructure such as water hookups or dockside power, requiring field teams to deploy fully independent tool systems and energy sources designed for quiet, low-impact operation.

Technicians working in these environments often manage personalized service plans, including ongoing preventive care and seasonal system checks. For high-end vessels, this may include advanced diagnostics on stabilizers, tender lifts, or integrated HVAC systems. Security clearance and pre-visit coordination are standard, and digital service records are often shared with yacht managers or property personnel to maintain transparency and continuity of care.

Actions You Can Take

Use Scheduling Tools That Adapt to Field Conditions

Effective marine service scheduling must accommodate unpredictable job durations, environmental delays, and client cancellations. Scheduling systems also support tiered job priority logic—assigning emergency work higher placement in the daily queue while auto-deferring lower-priority requests. These systems also allow pre-loading of vessel-specific requirements into the work order, minimizing on-site prep and increasing technician accuracy.

Standardize Internal Communication and Documentation

Rather than relying on technician recall or fragmented chat logs, implement communication protocols that log all job-related actions within a centralized interface. This allows supervisors to monitor comments, track task modifications, and validate technician notes in real time. When tied to digital job cards, this structure captures critical service context for future reference.

Structured documentation workflows also enable curated reporting. Technicians submit data through customized forms with asset-specific fields—drastically improving the quality of inspection records. This is especially valuable for vessels under warranty or requiring insurance documentation post-incident. The ability to export these records into audit-ready formats mitigates compliance risk and accelerates downstream approvals.

Leverage Preventive Service Packages and Recurring Schedules

Recurring service offerings provide a steady revenue stream and elevate long-term relationships with vessel owners. These packages often include seasonal recommissioning, engine fluid analysis, and corrosion prevention tasks—services that extend equipment life while lowering reactive maintenance costs. By offering tiered service plans, companies can scale offerings based on vessel use, size, or propulsion type.

When tied to calendar-based automation, these plans allow clients to receive proactive reminders, digital checklists, and package renewals without manual coordination. Systems that track service intervals by engine hours or battery cycles further refine timing, delivering just-in-time care. For fleet clients, consolidated reporting across all vessels supports compliance documentation and warranty validation.

1. Evaluate Current Workflow

Workflow evaluation forms the baseline for any operational upgrade. Without a clear understanding of how jobs are scheduled, dispatched, and completed, optimization efforts remain reactive and fragmented. Start by conducting a full service architecture review—from intake protocols to technician debriefs—and document the handoffs, dependencies, and support systems involved. Incorporate real-time service logs, technician performance data, and system-generated timestamps to identify procedural blind spots that may not be obvious in static process maps.

A more advanced approach includes layering in service exception data—instances where job duration exceeded estimates, repeat visits occurred, or tasks were deferred due to part availability. These anomalies provide a sharper diagnostic lens than average job times or revenue metrics alone. Cross-reference these findings with environmental variables such as vessel location types or access restrictions to detect patterns that hinder operational consistency. Prioritize failure points with downstream impact, such as misaligned inventory requests or incomplete digital estimates, and isolate their root causes.

Translate Findings into Operational Adjustments

Once patterns are validated, transition from analysis to iterative refinement. Select high-leverage adjustments that support both technician autonomy and back-office control. For example:

- Disconnected job briefs: Deploy mobile-accessible templates that include vessel specs, last service outcomes and customer requests.

- Unstructured job routing: Apply dynamic scheduling software that accounts for technician qualifications, tide windows, and site-specific access protocols.

- Inefficient part utilization: Shift to serialized parts tracking that links usage to specific job IDs and failure codes, enabling predictive restock cycles.

These refinements lay the groundwork for scalable marine service workflow optimization. They also enable future enhancements—such as AI-driven dispatch logic or technician performance modeling—by structuring the underlying operational data.

2. Implement Scheduling Tools

After addressing workflow inefficiencies, the next priority lies in the intelligent allocation of technician time. Static calendars and manual dispatching cannot support the operational demands of mobile marine services, where access restrictions, environmental conditions, and shifting client priorities complicate daily planning. Marine service scheduling platforms with responsive logic create a centralized view of capacity, enabling coordinators to keep jobs flowing smoothly while minimizing gaps in technician deployment.

These systems adapt to field conditions and service constraints in real time—accounting for not only technician skill sets and location, but also access windows at gated marinas, restricted harbor operations, and client-specific service plans. Sophisticated schedulers can sequence tasks based on berth proximity, site access limitations, or dock equipment compatibility. This level of granularity ensures service personnel arrive fully prepared, with minimal margin for delay or rescheduling.

Automate, Prioritize, and Adapt in Real Time

Automation enhances consistency. Instead of dispatchers manually sending updates, the system issues confirmations, status changes, and ETA adjustments as jobs progress. Notifications are updated dynamically based on technician location and task completion, giving clients a reliable view of when to expect service without requiring follow-up. This reduces administrative burden and improves transparency—particularly helpful when coordinating service at private docks or residential marinas where access may be restricted without prior notice.

To handle unpredictable demand, some scheduling platforms allow configurable buffer zones built into daily calendars. These flex periods are not hard-coded slots, but intelligent placeholders that shift based on job overruns, cancellations, or urgent requests. When integrated into routing logic, these flexible intervals absorb excess workload without affecting the downstream schedule. This approach preserves technician efficiency while maintaining availability for time-sensitive jobs, including emergency haul-out inspections or post-storm diagnostics.

Key Features That Drive Performance Gains

Marine service scheduling platforms that deliver measurable efficiency gains share several critical functions designed to support the field environment:

- Predictive Routing: Uses historical traffic data, technician performance, and service duration patterns to develop optimized travel sequences. This reduces idle time and improves fuel efficiency across multi-stop service routes.

- Live Job Monitoring: Displays technician progress, service milestones, and estimated completion windows in real time. Enables dispatchers to reassign deferred tasks or reroute technicians to a nearby vessel when cancellations occur.

- Event-Triggered Notifications: Sends context-sensitive alerts based on technician status changes, such as en route, delayed, or service complete. Clients receive updates aligned to service progress, not static timelines.

- Contingency Capacity Management: Maintains protected scheduling zones for high-priority or last-minute service calls. These slots shift dynamically based on job progress throughout the day, ensuring the team can absorb urgent work without cascading delays.

These capabilities elevate day-to-day operations by aligning technician availability with site logistics and service scope. When implemented correctly, they reduce labor inefficiencies and enable consistent delivery—even as service volumes fluctuate or clients request last-minute changes.

3. Standardize Communication Protocols

Once scheduling tools are in place, the next layer of operational control centers on communication flow—both internal and external. Without a defined structure, remote teams rely on disjointed updates that slow down task execution and elevate the risk of service inconsistencies. Effective protocols ensure the right information—service changes, technical documentation, and client authorizations—moves between field and office without delay or misinterpretation.

Technicians, coordinators, and clients must operate from a unified system of record. A centralized communication hub that links directly to work orders, equipment history, and maintenance logs enables seamless coordination without relying on parallel systems. When structured correctly, this environment supports version control on service documents, timestamped technician inputs, and immediate updates to job status—all without the need for back-and-forth clarification. Coordination becomes proactive rather than reactive, especially when dealing with multi-vessel fleets or clients with strict service level agreements.

Structure, Consistency, and Real-Time Visibility

Standardizing outbound communication begins with the development of configurable templates tailored to the mobile marine environment. These templates should support conditional logic, adapting invoice terms, service descriptions, or compliance verbiage based on the vessel class, engine type, or geographic region. For example, a diesel-powered commercial fishing vessel may require carbon emissions disclosures or fuel system summaries, while a recreational powerboat may need owner-facing care instructions after service. This reduces errors and enhances client understanding across varied vessel profiles.

Client communication should align with operational triggers, but also reflect the context of the service event. When a technician identifies a secondary issue during a routine inspection, the system should generate a pre-formatted message that includes the risk level, estimated time impact, and whether the part is in stock. This level of detail allows clients to make informed decisions quickly, avoiding delays caused by vague updates. Communication becomes a tool for trust-building, not just status reporting.

4. Prioritize Preventive Maintenance

Preventive maintenance serves as a critical control point in reducing unplanned service interruptions, minimizing emergency dispatches, and increasing the lifespan of onboard systems. Without a structured approach to recurring inspections and component-specific interventions, field operations remain reactive—compounded by missed failure indicators, repeat visits, and unnecessary part replacements. A proactive strategy built around real-time data, vessel operating profiles, and component-level monitoring creates stability across maintenance cycles.

Standardizing technical procedures around vessel class, system complexity, and operating environment allows teams to allocate resources with greater precision. Service templates should align with manufacturer recommendations but be refined through insights from field diagnostics and historical performance. For example, implementing failure mode effect analysis (FMEA) on key propulsion and electrical systems allows for customized service intervals based on actual failure trends. These data-informed intervals better reflect wear rates than time-based schedules alone—especially for vessels with variable usage patterns or mixed operating conditions.

Packaging Preventive Services for Operational Efficiency

To maximize technician utilization and streamline job sequencing, preventive maintenance tasks should be bundled into modular service kits aligned with vessel usage cycles. These packages are not static—they must be dynamically assembled based on equipment configuration, usage data, and seasonal readiness requirements. For example:

- Integrated mechanical and software audits: Combined propulsion system inspection and firmware verification for vessels with digital throttle control or integrated helm displays.

- High-cycle engine performance reviews: Includes wear analysis on injectors, turbocharger inspection, and boost pressure validation—targeted at commercial vessels exceeding standard duty cycles.

- Environmental risk mitigation packages: Focused on corrosion-prone components in brackish or tropical waters, including bonding system verification and sacrificial anode mapping.

Each package is tied to technician specialization, part inventory levels, and required diagnostic tooling. Scheduling platforms that incorporate these variables can auto-generate prep lists, assign qualified personnel, and stage parts for on-site delivery. This reduces lead time between job dispatch and execution while maintaining alignment with marine operations best practices. When executed consistently, preventive maintenance becomes a measurable performance driver, not just a scheduled obligation.

5. Streamline Billing and Payments

Financial processes in mobile marine business must operate with the same agility and precision as field service workflows. When billing and payment systems are disconnected from real-time service activity, businesses face delayed cash flow, manual reconciliation errors, and increased administrative overhead. Embedding financial transactions directly into the service pipeline ensures that work completed in the field translates immediately into revenue recognition.

Technicians should finalize billing at the job site using mobile-enabled systems that automatically populate labor, materials, and service codes based on the completed tasks. These tools eliminate the friction of post-service data entry and reduce the risk of missing line items or misclassified charges. When integrated with marine service management software, these platforms also maintain synchronized customer profiles, ensuring accurate tracking of open balances, service history, and credit terms across the organization.

Accelerating Cash Flow with Seamless Payment Infrastructure

Flexible payment options are essential for improving collection rates and enhancing customer satisfaction in marine services. Systems that support secure mobile terminals, card-on-file processing, and digital invoicing links allow clients to pay on their terms without requiring follow-up from office staff. For technicians working in areas with poor connectivity, offline-capable payment apps ensure that transactions are captured in the field and synced automatically once a connection is restored.

Bundled service offerings—such as engine diagnostics paired with seasonal commissioning—help standardize pricing while increasing ticket value. These bundles reduce invoice complexity and provide clear value to customers, particularly when presented as pre-defined service packages within digital quotes. Templates configured in the billing system enable fast selection and reduce time spent customizing estimates, making it easier for field staff to stay focused on service delivery.

Enhancing Financial Oversight with Real-Time Analytics

Visibility into financial performance is critical for marine operations managers overseeing distributed service teams. Dashboards that track revenue in real time—broken down by technician, location, service category, or customer segment—allow for more accurate forecasting and immediate identification of underperforming areas. This level of insight supports better resource allocation, pricing decisions, and strategy adjustments during seasonal fluctuations.

Integrated reporting tools transform routine transactions into actionable data. These systems automatically categorize invoices, apply tax codes, and generate audit-ready summaries without requiring secondary data entry. For small marine businesses, this reduces reliance on third-party accounting integrations and supports tighter control over profit margins. When used effectively, these tools align financial visibility with operational decision-making, giving owners a consistent view of how field activity drives business performance.

6. Measure Customer Satisfaction

Understanding customer satisfaction provides critical insight into operational performance, and long-term service viability. In mobile marine service businesses, where the technician represents the business at the dock, ramp, or port, each interaction becomes a direct reflection of brand reliability. Service consistency across varied environments—whether a private yacht club or a commercial fishing slip—requires that customer perception is continuously measured and analyzed.

Post-service surveys delivered via SMS or email should be short, structured, and initiated promptly after service completion. Timely outreach ensures feedback is tied to the immediate experience, increasing accuracy and response rates. Surveys should focus on measurable elements such as clarity of communication, resolution time, and technician preparedness. Well-structured surveys also allow for segmentation by vessel type, service category, or technician, enabling more precise operational adjustments.

Using Satisfaction Metrics to Shape Service Strategy

Client feedback often reveals more than individual service outcomes—it surfaces recurring expectations and gaps in service offerings. If multiple clients mention a lack of proactive updates or post-service documentation, those signals can justify investments in communication protocols or automated reporting. Comments regarding scheduling flexibility or bundling preferences can inform new service tiers or membership-style plans tailored for high-frequency users.

Incentivized feedback programs—such as limited-time discounts for detailed service reviews—encourage more thoughtful responses. These programs not only increase participation but also position the business as responsive and improvement-focused. When feedback mechanisms are built into the broader operational framework, they help align service delivery with client expectations while supporting ongoing workflow optimization across the entire mobile marine service model.

Reasons to Focus on Operational Efficiency

Operational efficiency underpins the scalability and resilience of any mobile marine service business. By refining internal systems and aligning field execution with centralized oversight, teams create service environments that can support growth initiatives such as fleet contracts, multi-vessel programs, or expansion into underserved coastal regions. With the right infrastructure in place, operators can pursue strategic partnerships or shift toward higher-margin services that require greater execution discipline.

Reputation, Retention, and Resource Control

Efficiency enables tighter alignment between client expectations and service outcomes—particularly when delivering complex or multi-phase jobs. Structured operations allow providers to offer value-added capabilities such as scheduled diagnostics, recurring care plans, or project-based upgrades across multiple systems. This level of consistency makes it easier to build trust with vessel owners, captains, and fleet managers who rely on dependable scheduling and documented service workflows. Over time, these relationships generate sustained revenue through multi-season commitments and bundled service agreements.

Internally, structured operations reduce exposure to administrative overload and role ambiguity. Streamlined data capture, mobile checklists, and auto-synced work logs allow technicians to focus on diagnostics and client interaction while back-office teams maintain oversight through centralized dashboards. These systems support better workforce allocation, reduce redundant communication, and free up bandwidth for service improvements or technician development programs. In high-output operations, this balance creates operational slack—space to innovate without sacrificing throughput.

Adaptability During Demand Surges and Operational Disruptions

As marine service demand fluctuates with seasonal boating schedules, regulatory deadlines, or weather-related surges, operational flexibility becomes a competitive differentiator. Teams with adaptive scheduling frameworks and automated job reprioritization can dynamically reassign resources without compromising job quality. This fluidity supports business continuity during peak season, allowing for expanded capacity without proportionally increasing overhead or risking technician burnout.

Operational resilience also plays a vital role in risk mitigation. When external disruptions—such as supply chain delays, restricted marina access, or vendor failures—impact service readiness, well-structured workflows allow teams to deploy alternate job types, pivot to diagnostics, or reallocate technicians toward high-availability service packages. Coordinators can maintain control by referencing real-time dashboards that display technician location, job complexity, and resource availability across active zones. This level of responsiveness ensures service pipelines remain active, even under unpredictable operating conditions.

Final Thoughts

As mobile marine service models advance, competitive resilience depends on how effectively businesses unify field execution with operational intelligence. Beyond core service delivery, the long-term differentiator lies in a systemized ability to capture, analyze, and act on service data in real time—from condition-based maintenance triggers to technician performance metrics. This level of integration creates fluid, high-output workflows that adjust dynamically to changing vessel demands and field conditions.

Scaling service capability requires alignment between infrastructure readiness and technician autonomy. Rather than expanding through volume alone, operators benefit from refining task orchestration—ensuring each technician is deployed with full situational context, calibrated tools, and pre-qualified job scopes. When matched with adaptive scheduling and parts traceability, this precision reduces friction and supports consistent execution even in logistically complex environments like gated marinas or commercial ports.

High-frequency clients—such as fleet operators, yacht managers, and charter services—expect continuity, documentation accuracy, and proactive issue resolution. Meeting those expectations calls for a strategic shift: treating every service event as a data point that informs broader asset management, compliance verification, and lifecycle planning. When performance insights are institutionalized across the operation, the mobile service model becomes a platform for sustained value—not just reactive support.

Frequently Asked Questions

Managing mobile marine service operations effectively demands more than route planning or quick turnaround—it requires operational foresight supported by integrated systems. Establish a connected service chain that aligns technician mobilization with real-time data from scheduling, service diagnostics, and inventory platforms. Each job should transition seamlessly from intake to completion, with pre-loaded service histories, task-specific instructions, and automated documentation.

Refinement should also extend to technician deployment strategy. Assign resources not just by availability, but by matching technical expertise to task complexity and vessel class. This precision reduces rework and ensures consistent outcomes across variable environments—whether servicing a trailered vessel at a launch ramp or conducting a sensor calibration at a commercial port.

Software improves operational efficiency by removing the dependency on reactive processes. Real-time dashboards allow managers to oversee technician location, job progress, and inventory availability simultaneously, enabling swift adjustments when disruptions occur. By integrating condition-based alerts and scheduling intelligence, software also helps prioritize preventive maintenance over emergency calls, improving resource utilization and reducing cost per job.

When platforms sync across mobile and desktop environments, field data collected by technicians—photos, part usage, job notes—feeds directly into billing and client records. This reduces administrative time, eliminates data re-entry errors, and ensures financial reconciliation aligns with actual work performed. The result is a closed-loop service model where field activity and business metrics remain tightly linked.

Select software that supports the fluid and often unpredictable nature of marine service delivery. Crucial features include:

Dynamic technician assignment: Routes jobs based on proximity, skill set, and current workload for optimal coverage.

Integrated vessel profiles: Links service records, inspection outcomes, and maintenance schedules to specific hull IDs or engine serial numbers.

Real-time status updates: Visual dashboards that reflect job start, pause, and completion times for dispatch visibility.

Analytics-driven reporting: Tracks job cycle times, part consumption, and technician productivity to guide strategic decisions.

These capabilities must function consistently across environments—from commercial ports with restricted access to private docks with limited infrastructure.

Enhancing satisfaction begins with precision and predictability. Provide clients with comprehensive service estimates that clearly define scope, labor, and timeline. Set accurate expectations from the first touchpoint—then meet or exceed them with punctual, well-prepared technicians who communicate updates clearly and professionally.

Post-service, deliver value through detailed digital reports that include condition assessments, part replacements, and visual documentation. For clients managing fleets or high-value assets, offer trend analysis over time—showing how preventive maintenance has reduced failure rates or improved performance. This shifts the relationship from transactional to consultative, strengthening client trust and increasing long-term retention.